Products defined as machinery are subject to various regulations, safety standards, labelling, documentation, and testing requirements in the United Kingdom. Ensuring compliance is critical, as unsafe machinery can result in severe injuries or even death.

In this guide, we explain how regulations such as The Supply of Machinery (Safety) Regulations 2008 and The Noise Emission in the Environment by Equipment for Use Outdoors Regulations 2001 apply to machinery sold in the United Kingdom.

Note: This article does not cover requirements for Northern Ireland, which is generally aligned with EU product safety requirements.

Content Overview

FREE CONSULTATION CALL (US, EU & UK)

- Request a free 30-minute call with Ivan Malloci to learn how we can help you with:

- Find product requirements

- Certification and labeling

- Lab testing

The Supply of Machinery (Safety) Regulations 2008

The Supply of Machinery (Safety) Regulations 2008 establish safety requirements for machinery, which are defined as assembled devices with at least one motorised part, designed to perform specific tasks, either alone or combined with other equipment.

Here are some examples of machinery:

- Power tools

- Agricultural machinery

- Food processing machinery

- Centrifuges

- Conveyor belts

The regulations generally require importers and manufacturers to:

a. Ensure that the machinery satisfies the safety requirements by following the appropriate conformity assessment procedure and standards

b. Draft the technical documentation

c. Provide information for the machinery’s operation, such as instructions

d. Create a Declaration of Conformity

e. Affix the UKCA marking onto the machinery

f. Affix product traceability information

g. Affix pictograms and warnings, where appropriate

Designated standards

Manufacturers should use designated standards to ensure that their machinery complies with the safety requirements of the regulations. While there are many designated standards for machinery, here we provide some examples:

EN 115-1 – Safety of escalators and moving walks – Part 1: Construction and installation

EN 12547 – Centrifuges – Common safety requirements

EN 12882 – Conveyor belts for general purpose use – Electrical and flammability safety requirements

EN 14466 – Fire-fighting pumps – Portable pumps – Safety and performance requirements, tests

EN 13684 – Garden equipment – Pedestrian controlled lawn aerators and scarifiers – Safety

EN ISO 28927-7 – Hand-held portable power tools – Test methods for evaluation of vibration emission – Part 7: Nibblers and shears

EN ISO 28139 – Agricultural and forestry machinery – Knapsack combustion-engine-driven mistblowers – Safety requirements

EN 50580 – Safety of hand-held electric motor operated tools – Particular requirements for spray guns

Essential requirements

Schedule 2 of the regulations lists the essential health and safety requirements that machinery needs to comply with:

a. General remarks on materials, lights, and more

b. Control system requirements

c. Protection against mechanical hazards (e.g. accessible machinery parts should not have sharp edges that could cause injury)

d. Characteristics of guards and protective devices (e.g. interlocking movable guards should remain attached to the machinery when they are open)

e. Risks due to other hazards (e.g. the machinery’s construction should prevent fire risk or overheating)

f. Maintenance (e.g. maintenance points should be positioned away from danger zones on machinery)

g. Information (e.g. machinery should bear warning symbols or pictograms)

Note that there exist also requirements that are specific for certain machinery, such as foodstuffs machinery.

Conformity assessment procedures

A conformity assessment procedure is necessary to determine the compliance of the different types of machinery. Specifically, machinery that falls into a category not indicated in Annex IV should undergo the conformity assessment with internal checks, as set in Annex VIII (Part 8 of Schedule 2).

Conversely, machinery that falls in a category referred to in Annex IV (Part 4 of Schedule 2) should undergo one of the following conformity assessments:

a. The conformity assessment procedure with internal checks, set in Annex VIII (only possible if the product is manufactured per the requirements of designated standards), or

b. The type-examination procedure, set in Annex IX (Part 9 of Schedule 2) and point 3 of the internal checks procedure from Annex VIII, or

c. The full quality assurance procedure, set in Annex X (Part 10 of Schedule 2)

Approved bodies

Approved bodies are entities authorised to carry out conformity assessments and certifications for products sold in the United Kingdom, against UK requirements.

Manufacturers need the services of an approved body in order to complete some conformity assessments, that is the type-examination procedure and the full quality assurance procedure.

Documentation

Here we list the documentation requirements set by the regulations.

| Title | Description |

| Declaration of Conformity | You should create a Declaration of Conformity to declare that the machinery complies with the relevant requirements.

The provision of this document is mandatory and needs to contain the items in Part 1, Section A, of Annex II. |

| Declaration of incorporation | The Declaration of Incorporation applies to machinery that is partly completed. It needs to contain the items listed in Part 1, Section B, of Annex II. |

| Technical file | You should also provide a technical file containing the items listed in Part A of Annex VII. |

| Instructions | You should provide instructions for operating, assembling, using, and maintaining the machinery. The instructions should contain the information listed in Schedule 2 Part 1.7.4.2. |

| Test report | The regulations mandate product testing and the subsequent provision of test reports in the technical file. |

Labelling requirements

In this section, we list the key labelling requirements set by the regulations.

| Title | Description |

| UKCA marking |

The UKCA marking indicates the machinery’s compliance with the requirements of the regulations. If the machinery underwent the full quality assurance procedure in Annex X, the UKCA marking should be followed by the approved body’s identification number. |

| CE marking |

The UK indefinitely accepts the usage of the CE marking for machinery. Thus, the manufacturers can choose to apply the CE marking instead of the UKCA marking. The CE marking should also precede the notified body’s identification number if the machinery underwent the full quality assurance procedure in Annex X. |

| Product traceability | The machinery should bear the following information:

|

| Warning symbols and pictograms | Different machinery may necessitate different types of warnings and pictograms. You can find more information in Schedule 2 Part 1.7.1. |

The Noise Emission in the Environment by Equipment for Use Outdoors Regulations 2001

The Noise Emission in the Environment by Equipment for Use Outdoors Regulations 2001 sets noise emission requirements for outdoor-use equipment such as:

- Compaction machines (e.g. those with vibratory plates)

- Combustion-engine driven construction winches

- Hydraulic power packs

- Brush cutters

- Portable chain saws

The regulations exclude from the requirements:

a. Non-powered attachments sold separately, except for those for hydraulic hammers and hand-held concrete breakers and picks

b. Equipment meant for transporting people or products by air, rail, road, or waterways

c. Equipment intended for emergency, police, and military purposes.

The regulations generally require importers and manufacturers of covered products to:

a. Adhere to the permissible sound power level

b. Ensure that the product undergoes the appropriate conformity assessment procedure

c. Draft the Declaration of Conformity and technical documentation

d. Affix the UKCA marking and the indication of the guaranteed sound power level

e. Affix traceability information

Standards

The regulations list two basic noise emission standards in Schedule 6 Part A, which should be used to determine the sound power level of outdoor-use equipment:

EN ISO 3744 – Acoustics — Determination of sound power levels and sound energy levels of noise sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane

EN ISO 3746 – Acoustics — Determination of sound power levels and sound energy levels of noise sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting plane

Conformity assessment procedures

Different machinery should undergo different conformity assessment procedures.

Machinery listed in Schedule 1 should undergo either:

a. The internal production control with technical documentation assessment procedure in Schedule 9, or

b. The unit verification procedure in Schedule 10, or

c. The full quality assurance procedure in Schedule 11

Here are some examples of such machinery:

- Compressors with a power lower than 350 kW

- Dumpers with a power lower than 500 kW

- Hydraulic power packs

- Lawn trimmers

Machinery listed in Schedule 2 should undergo the internal production control procedure in Schedule 8. Here are some examples of machinery listed in Schedule 2:

- Brush cutters

- Portable chain saws

- Compaction machines

- Drill rigs

Approved bodies

An approved body authorised by the Secretary of State must carry out the conformity assessment procedure for machinery listed in Schedule 2.

Documentation

Here we summarise the documentation items that the manufacturer should provide:

- Declaration of Conformity

- Technical documentation

- Instructions

- Test report

Labelling requirements

Here we summarise the labelling requirements as set by the regulations:

- UKCA marking (or CE marking, which is accepted indefinitely by the regulations)

- Traceability information

- Indication of guaranteed sound power level

REACH Regulation (EC) 1907/2006

The REACH Regulation (EC) 1907/2006 restricts substances on their own, in mixtures and in articles, which include machinery and their components.

Additionally, the REACH Enforcement Regulations 2008 establishes requirements for enforcing REACH Regulation (EC) 1907/2006.

Note that while the REACH Regulation (EC) 1907/2006 in the UK is based on the EU’s REACH Regulation, there may be differences between the two in terms of specific substance restrictions.

Restricted Substances (Annex XVII)

Annex XVII lists restricted dangerous substances, including those used in machinery. Here we list some examples:

a. Cadmium – banned from use in cadmium plating metallic components of machinery for:

- Food production

- Agriculture

- Cooling and freezing

- Printing and book binding

- The production of household goods

- The production of furniture

- The production of sanitary ware

- The production of central heating and air conditioning plant

- The production of paper and board

- The production of textiles and clothing

b. decaBDE – restricted in spare parts of machinery.

c. Monomethyl — tetrachlorodiphenyl methane

Note that some substances – such as some types of phthalates, are restricted in articles in general. Thus, these restrictions would also apply to machinery and their parts.

UK REACH Candidate List

The UK REACH Candidate List contains substances of very high concern (SVHCs) that are carcinogenic, mutagenic, reprotoxic (CMR), persistent, bio-accumulative, and toxic. Machinery may contain listed SVHCs, such as:

- Lead – in the electronics and metal components of machinery, for example

- Phthalates – in PVC components of machinery, for example

Machinery testing

You should have your machinery undergo testing to prove compliance with safety requirements. Machinery testing is normally based on safety standards, such as EN 50580, which is designated under The Supply of Machinery (Safety) Regulations 2008.

Besides that, you should also test your product against relevant restricted substances, such as cadmium or decaBDE.

If your machinery passes testing, you should receive a test report proving that your products comply with the regulatory requirements.

Approved Bodies for Machinery

You need third-party assessment bodies that are approved by the UK government to assess certain categories of machinery. You can find such bodies on the UK’s Find a UK Market Conformity Assessment Body website by filtering for “Approved Body”, and “Machinery”. Here we list some approved bodies that can carry out assessments on products covered by The Supply of Machinery (Safety) Regulations 2008:

- CEM International Ltd

- Safenet Limited

- Technology International (Europe) Ltd

- Lift Cert Limited

- British Engineering Services Ltd

Additional Requirements

In some cases, machinery may be subject to some additional requirements, such as the ones listed in this section.

| Regulation | Description |

| The General Product Safety Regulations 2005 | The General Product Safety Regulations 2005 cover products used by consumers. Specifically, it sets requirements for aspects of product safety not already covered by other regulations. The safety of machinery is generally covered by The Supply of Machinery (Safety) Regulations 2008, but The General Product Safety Regulations 2005 may still cover some safety aspects of some types of machinery that are used by consumers.

The General Product Safety Regulations 2005 generally require companies to:

|

| Persistent Organic Pollutants Regulation (EU) 2019/1021 | The Persistent Organic Pollutants Regulation (EU) 2019/1021 restricts the use of POPs or products that contain POPs.

Machinery may include plastic components, circuit boards, and electronic parts that may contain POPs. Here we list some examples of restricted substances that may be found in electronic components in machinery:

Note that the Persistent Organic Pollutants Regulations 2007 provide enforcement for the Persistent Organic Pollutants Regulation (EU) 2019/1021 in the United Kingdom. |

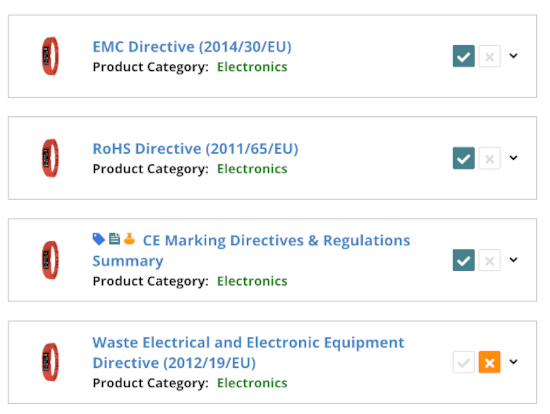

| Regulations for electronic products and components | Electronic machinery and their components may also have to comply with regulations that are specific for electronics, such as:

a. The Electrical Equipment (Safety) Regulations 2016 b. The Electromagnetic Compatibility Regulations 2016 c. The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012 d. The Radio Equipment Regulations 2017 e. The Ecodesign for Energy-Related Products Regulations 2010 f. Energy Labelling Framework Regulation (EU) 2017/1369 |

| Regulations for batteries | Battery powered machinery may also have to comply with battery regulations such as:

a. The Batteries and Accumulators Regulations 2008 b. The Waste Batteries and Accumulators Regulations 2009 |